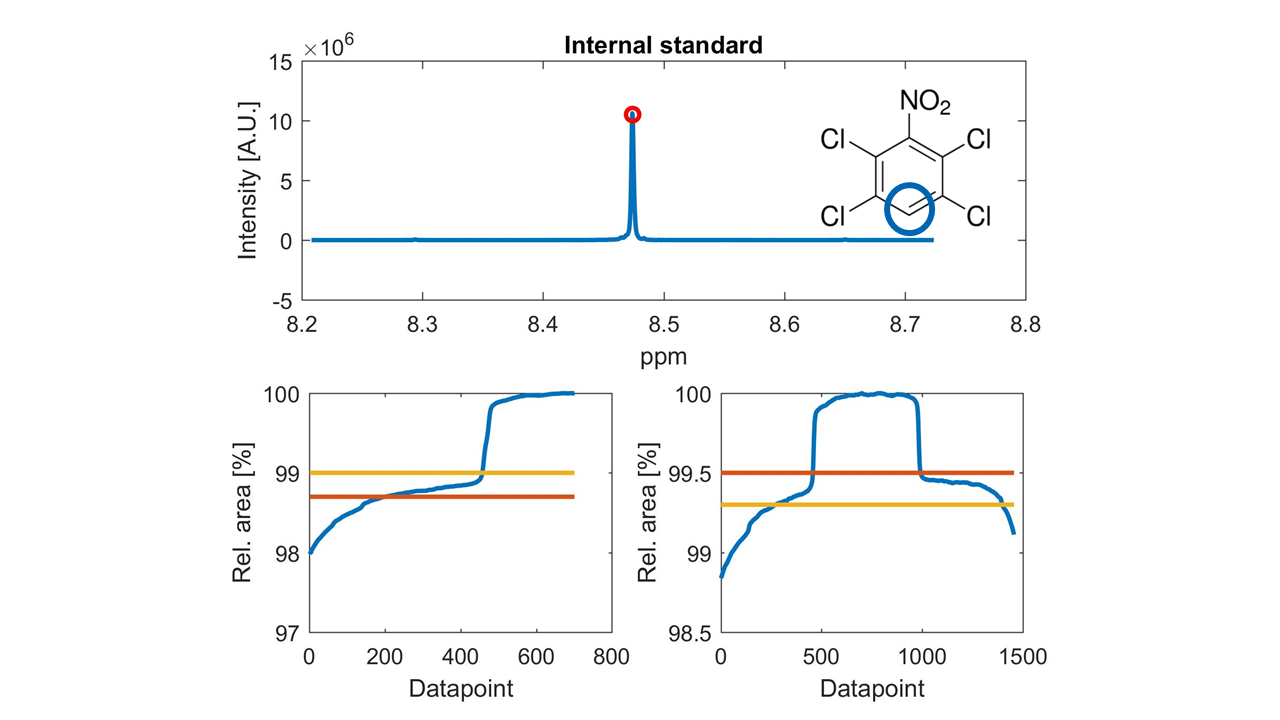

During several last year we have been developing a tool for automated qNMR analysis, which helps us to prevent typing errors during data evaluation and enables high throughput of the whole analysis workflow. This very fast routine also verifies preprocessing and integration steps in a fully automated manner. See the example of our frequently used internal standard 1,2,4,5-Tetrachloro-3-nitrobenzene (TCNB) in Fig. 1. The approach was successfully tested on binary mixtures of qNMR internal standards as well as complex multiplet patterns of pharmaceutical products. Now it is time for the next challenge!!!

Fig. 1 1H NMR spectrum of TCNB; quantification.

qNMR under GLP and GMP

As a GMP/GLP accredited laboratory, we have to assure that only qualified personal is involved in sample preparation for qNMR analysis. In December 2019 eight technicians and eight study directories performed 6-fold weighing of binary mixtures of reference material 2,6-Di-tert.-butyl-4-methylphenol (BHT) and internal standard 1,2,4,5-Tetrachloro-3-nitrobenzene (TCNB). All samples were measured by qNMR and were evaluated manually by a qNMR expert and automated routine.

Manual evaluation and automated routine

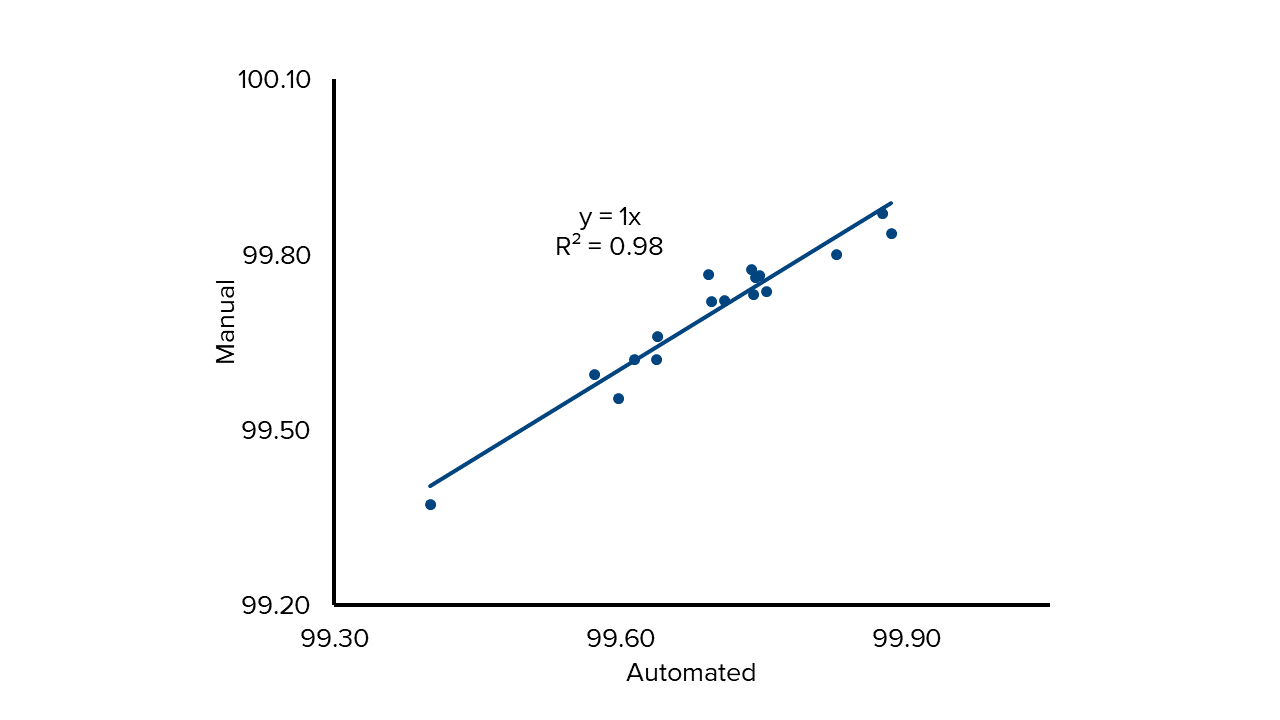

Fig. 2 shows the relation between mean values obtained by manual evaluation and automated routine. It can be seen that we obtained excellent linear equation with the slope of 1 and no offset. It means that the mean values are similar and both approaches are free of systematic error.

Fig. 2 Relation between mean values obtained by manual evaluation and automated routine.

Relative standard deviation

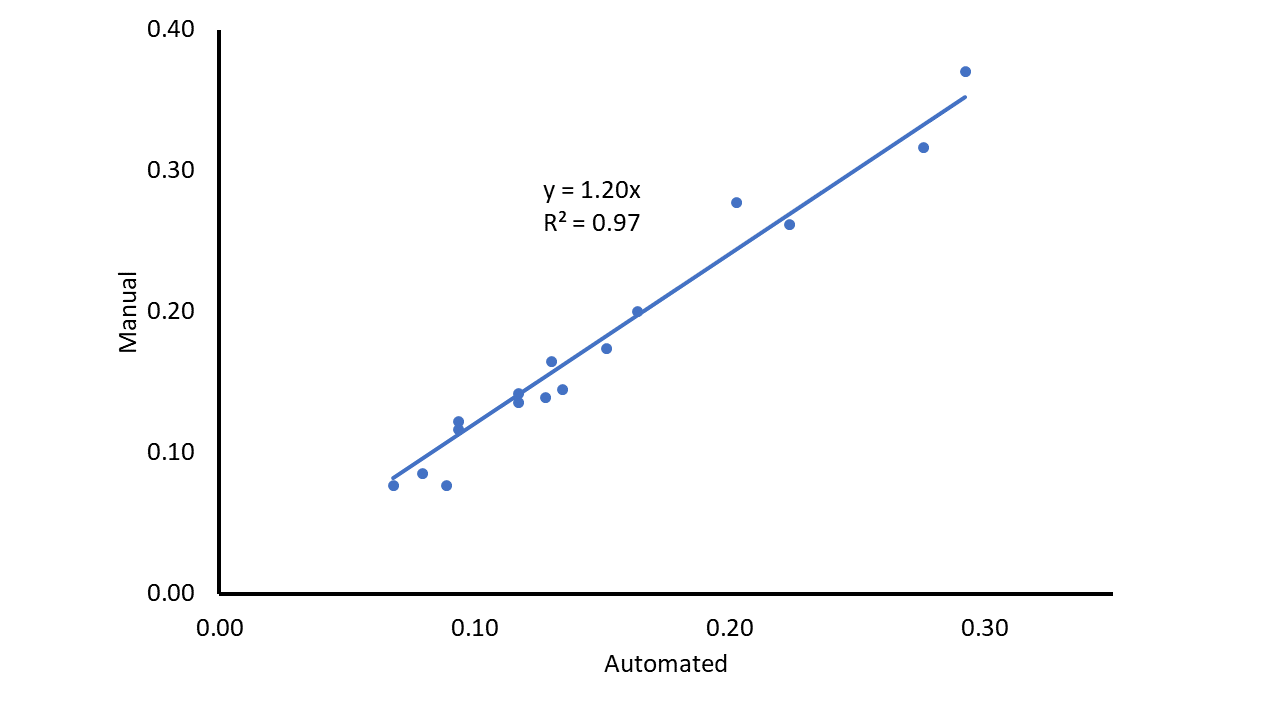

However, looking on relative standard deviation values from each of 6-fold determination, we noticed a profound decrease in uncertainty of approximately 20% using automation (Fig. 3). Now we can reduce qNMR uncertainty even more, the maximum was approximately 0.35%. This is a dream for competing methods for quantitative analysis such as HPLC.

Fig. 3 Relation between RSD obtained by manual evaluation and automated routine.

Qualified technicians weighted more precisely than qNMR experts

Using principle component analysis of about 200 single qNMR results, we concluded that qualified technicians weighted more precisely than qNMR experts due to every day practicing in laboratory. Moreover, the third and the fourth weighting were the most stable ones (close to the corresponding mean value), the first and the sixth values deviated more from the mean value.

Different NMR signals being used for quantification

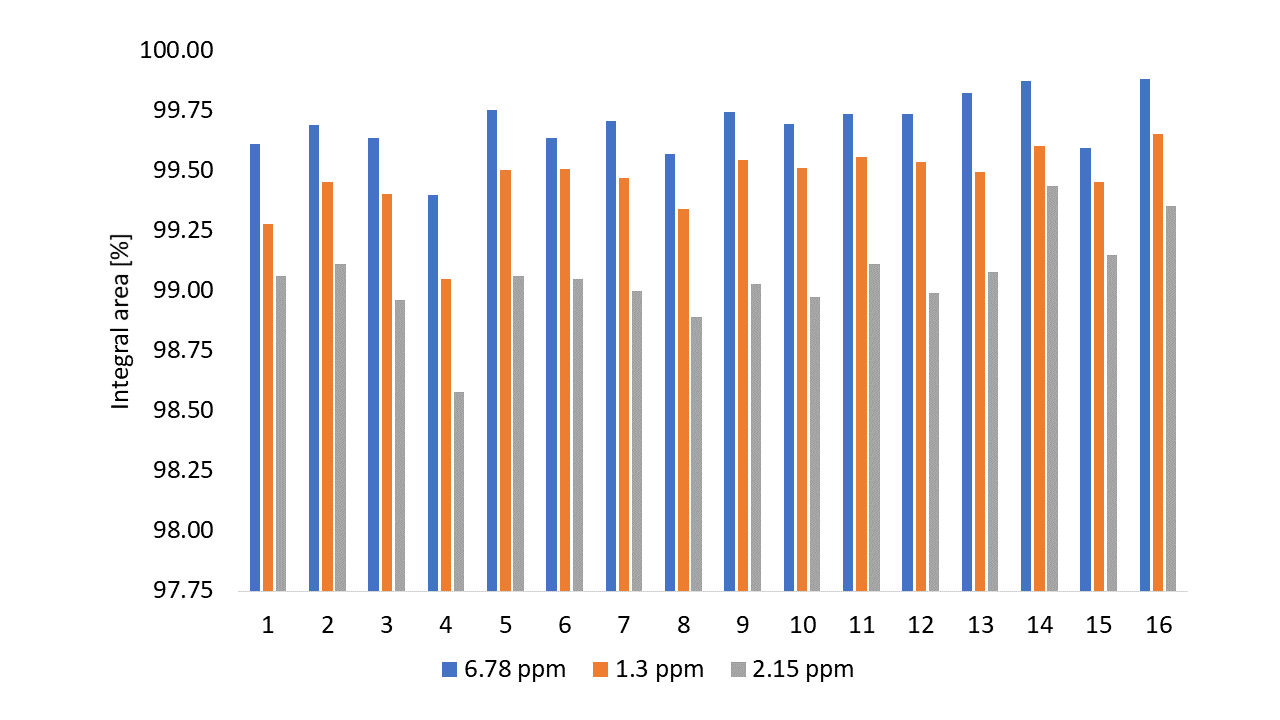

Since our test item (BHT) has several NMR signals, which can be used for qNMR evaluation, automated routine was tested on three cases (Fig.4). The mean values and corresponding standard deviations depend strongly on the signal used for qNMR. Namely, signal at δ 1.3 ppm has a very broad lineshape and the integral boarders are not enough to cover 100% of integral area. Another signal at δ 2.15 ppm is close to the solvent signal, and that again prevents accurate integration. Thus, our automated routine can easily identify deviation from “Scissors” qNMR requirements and help to find optimal conditions for integration.

Fig. 4 Mean values using different signals of the test item used for qNMR.

Our weighting training has shown that all participants have the competence, which is required to ensure correct results in sample preparation. Now introduce our routine as Macro in Topspin for spectra evaluation and looking forward to use it in routine practice to be faster, higher and stronger for our customers.

References:

- Yulia B. Monakhova, Bernd W.K. Diehl (2017) Practical guide for selection of 1H qNMR acquisition and processing parameters confirmed by automated spectra evaluation. Magn. Res. Chem. 55 (11): 996-1005

- Yulia B. Monakhova, Bernd W.K. Diehl (2017) Facilitating the performance of qNMR analysis using automated quantification and results verification. Magn. Res. Chem. 55 (9) 813-820

- Yulia B. Monakhova, Bernd W.K. Diehl (2018) Monitoring daily routine performance in quantitative NMR (qNMR) spectroscopy: Is the system suitability test necessary? Magn. Res. Chem. 57 (2-3) 110-117

Title picture: kindly provided by Mettler Toledo